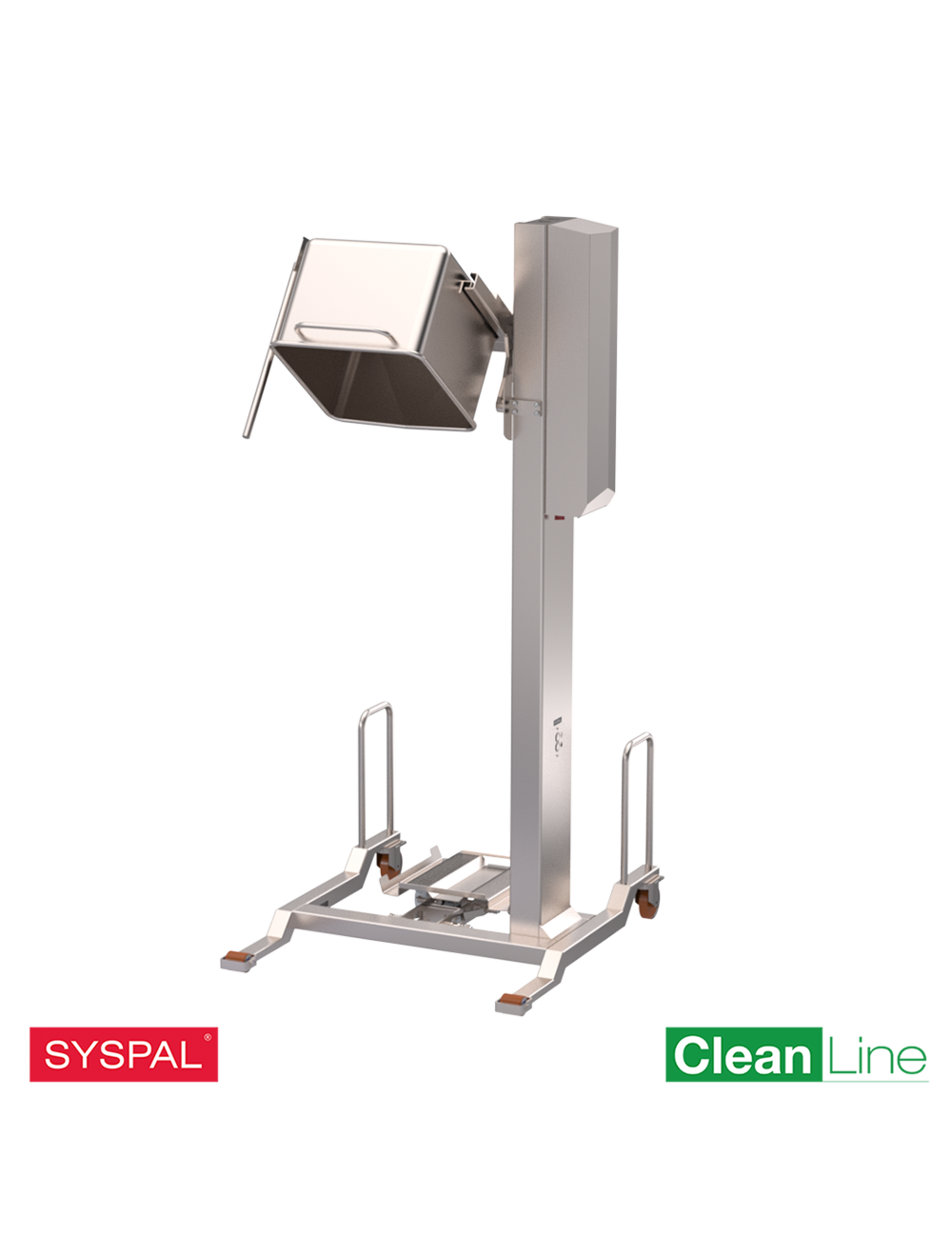

Clean Line Single Column Tipper Mobile

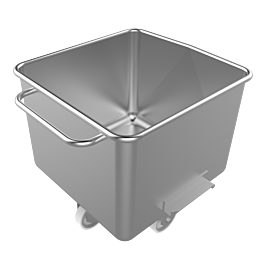

SYSPAL Clean Line single column lifter is another step towards improving best practice within your production space. The Clean Line Eurobin has a detachable base and our single column lifter has been designed to lift and tip the Eurobin whilst the base remains on the floor. With ever increasing hygiene standards and regulations, this lifter is a step towards improving your standards for food safety. The Clean Line single column lifter is also designed to work with standard 200L and 300L DIN 9797 Eurobins to provide flexibility throughout production.

- Designed for Clean Line compatible Eurobins and standard DIN9797 200L & 300L Eurobins

- Significantly reduces the risk of injury and accidents caused through manual handling operations

Speak to us about in stock equipment

Looking for more Clean Line Eurobin equipment?

View the full range of Clean Line Eurobin equipment here.

- Column heights, and tipping profiles designed to suit individual handling applications

- Up to 350kg SWL

- Grade 304 stainless steel construction

- Tipping angle: 145° max or 55° from horizontal

- Electrical requirements: 400v 3 phase

- Left or right hand lift columns

- Lifting carriages can be designed to handle a wide range of bowls, vessels, tanks, used in the food industry

- Mobile carriage frames available on a wide variety of the single column lifter models

Safety features:

- High & low level lift carriage limit switches

- Lift column chain guard

- Mechanical chain-break safety column – Prevents Euro Bin falling in the event of a chain failure

- Foot operated electro/mechanical safety mechanism on bin location arms – Prevents Lifter from operating if Euro Bin is not located in the lift carriage correctly

Roller tipping - Allows quick bin rotation and an increased tip angle of up to 55°. This assists in transfer of difficult or sticky product. Typical applications would be high viscosity liquids, dough and pastry products or prepared/IQF vegetables. (For use with 200 and 300 litre Eurobins as well as other containers.)

Curve tipping - Allows a more controlled tip function up to a tip angle of up to 40°. Ideal for installations where height restrictions are a limiting factor. Typical applications would be low viscosity liquids, such as stocks, sauces or free flowing grains, powders etc. (For use with 200 and 300 litre Eurobins.)

Track chute tipping - The combination of tip curve function and additional track mounted chute maximises product control when feeding cooking kettles or vessels for similar processes. Tipping angle up to 45°. (Can only be specified with 200 litre Eurobins.)