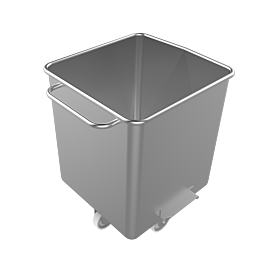

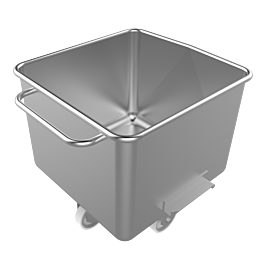

Eurobin Wash Frame Single Unit

Allows for safe, effective 360° cleaning access to the interior and exterior, including the base and wheel arrangements for 200L or 300L Eurobins

- Designed to significantly reduce the risk of injury and accidents caused through manual handling of Eurobins during the washing process

- Pneumatic cylinder operation with no electrics ensures the highest levels of safety in a wet room environment

- Hygienic 304 grade stainless steel construction

- Safe working load of 50kg

- The freestanding wash frame is designed for use by a single operator with Hold to Run pneumatic operation

- Quick cycle time to raise the bin to 100° tip angle ensures an accurate wash with excellent residual water drainage

- Location guides on frame allow for quick load and unload of Eurobin

- Part of the SYSPAL ‘Single Bin Solution’ for increased throughput, efficiency and hygiene

Looking for more Eurobin handling equipment?

View the full range of Eurobin equipment here.

SYSPAL Eurobin wash frames are designed to allow for the safe and effective manual washing of Eurobins and other food industry tanks and containers.

Hygienically designed and manufactured in 304 grade stainless steel specifically for food industry wash-down applications.

Use of single and double wash frame units remove the requirement for manual handling operations when cleaning and prevent damage sustained to Eurobins & containers during manual washing operations.

The carriage arm rotates and lifts the Eurobins clear from the wash room floor enabling operative access to all sides of the bin & holding in position at 10º from horizontal enables residual wash water to drain away.

The standard wash frame units are designed to handle both 200L and 300L Eurobins.

Lifting carriage arms can be designed and manufactured to accommodate a wide range of bowls, vessels, tanks and other food industry container types.

- Tipping angle range: 100° max from lowered position - 10° from horizontal position

- Max tipping height: 925mm