Bespoke Tray Racking & Transport

Bespoke Designs For Specific Applications

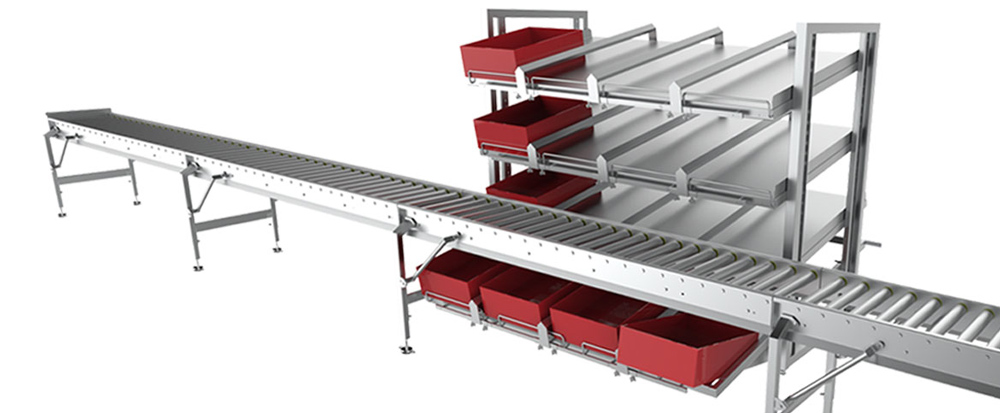

Gravity roller conveyor with custom-made tray flow racking for quick and efficient loading and unloading of polymer trays.

Used in this project:

Learn More About This Project:

With over 40 years of stainless steel manufacturing and design experience, developing bespoke solutions comes naturally to SYSPAL. Whether it's for a small piece of equipment to solve a challenging problem or a full production line, we are able to call upon a design team with extensive experience tailor a solution for you. This process is evident in the development of the above tray racking and conveyor system.

Our customer approached us to enquire if we could develop a ‘pick and pack’ system to improve and speed up their existing process. Although this was not a standard off-the-shelf product request, our design team were able to produce a system that could meet the customer's application requirements.

The resulting bespoke project design incorporated bespoke stainless steel flow racking designed specifically for the size of trays requested and a gravity roller conveyor. This was also designed to a specific length and angle to provide the correct speed of tray movement. The equipment is easy to wash down and maintain as it is constructed entirely from 304 and 316 grade stainless steel, ideal for use in hygienic environments. As the flow racking is attached to the conveyor it is much easier for an operative to pick items from the racking and pack into a tray quickly ready for transportation.

If you are interested in developing new ways for transporting product around your factory or making processes more efficient, don't hesitate to get in touch. Our design team will strive to meet any application requirements to develop a bespoke solution for you.

Bespoke Designs For Specific Applications

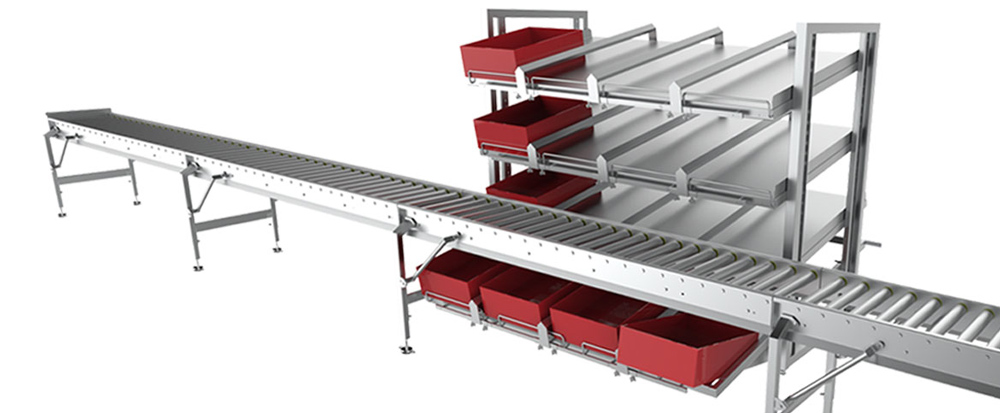

Gravity roller conveyor with custom-made tray flow racking for quick and efficient loading and unloading of polymer trays.

Used in this project:

Learn More About This Project:

With over 40 years of stainless steel manufacturing and design experience, developing bespoke solutions comes naturally to SYSPAL. Whether it's for a small piece of equipment to solve a challenging problem or a full production line, we are able to call upon a design team with extensive experience tailor a solution for you. This process is evident in the development of the above tray racking and conveyor system.

Our customer approached us to enquire if we could develop a ‘pick and pack’ system to improve and speed up their existing process. Although this was not a standard off-the-shelf product request, our design team were able to produce a system that could meet the customer's application requirements.

The resulting bespoke project design incorporated bespoke stainless steel flow racking designed specifically for the size of trays requested and a gravity roller conveyor. This was also designed to a specific length and angle to provide the correct speed of tray movement. The equipment is easy to wash down and maintain as it is constructed entirely from 304 and 316 grade stainless steel, ideal for use in hygienic environments. As the flow racking is attached to the conveyor it is much easier for an operative to pick items from the racking and pack into a tray quickly ready for transportation.

If you are interested in developing new ways for transporting product around your factory or making processes more efficient, don't hesitate to get in touch. Our design team will strive to meet any application requirements to develop a bespoke solution for you.